FABRICATION

SERVICES

AMADA LASER

The Amada Laser is a cutting-edge machine that excels in precision laser cutting operations. Leveraging advanced laser technology & high-power output, it can swiftly & accurately cut a wide range of materials with intricate detailing and complex shapes. The Amada laser’s versatility extends to rapid prototyping and handling various production requirements, making it a top choice for industries seeking efficient and high-quality cutting solutions.

AMADA PRESS BRAKE

The Amada Press Brake is a powerhouse in metal fabrication. With its high bending force & precision control, it can handle a wide range of sheet metal thicknesses and materials with ease. Advanced features, such as automatic tool changing and angle monitoring, enable it to produce complex bends & shapes efficiently. The machine’s versatility and performance make it a go-to choice for demanding bending applications in various industries

LASER WELDER

Babeco introduces our latest piece of equipment: The Miller OptX™ 2kW handheld laser welder. While this machine will boost our ability to weld up to 5/16 thickness material, it really shines and is ideal in sheet metal applications such as control boxes, sheet metal covers etc. Not only can the OptX weld, but it also has a cleaning setting where heat discoloration can be removed from a finished weld for aesthetics. Traditional welding processes arc essentially electrical welding arcs. They also require larger weld sizes as we create a welding puddle and penetration from the top down. With these processes we must create a hot fluid weld puddle that creates the base metal penetration. Laser welding utilizes light to fuse 2 materials together. Laser welding penetrates very deeply very quickly making it so that we do not have to wait for a puddle to be established before we start welding. This results in seeing much smaller laser welds compared to traditional welds that have similar strength.

Metal Types

- Mild steel

- Stainless steel and Nickel Alloys

- Galvanized

- Aluminum

- Titanium, Brass, Copper

- Dissimilar metals (eg: SS to copper)

Material Thicknesses

- Thin – down to 20ga (0.040)

- Thick to Thin

Joint Configurations

- Lap welds

- Fillet/inside corner welds

- Butt welds (prep with slight edge to follow)

- Outside corner – (Reconfigure fit up geometry)

- Spot/Plug welds

Arc Welding - Lower energy density

- Appx 100 W/mm^2

- Wide welds

- Heat is spread out

- Heat from top to bottom

- Heat from resistance of electrons

Laser Welding - Higher energy density

- Appx 100,000 W/mm^2

- Narrow welds

- Heat is highly focused

- Heat from within (focal point out)

- Heat from focused Light energy

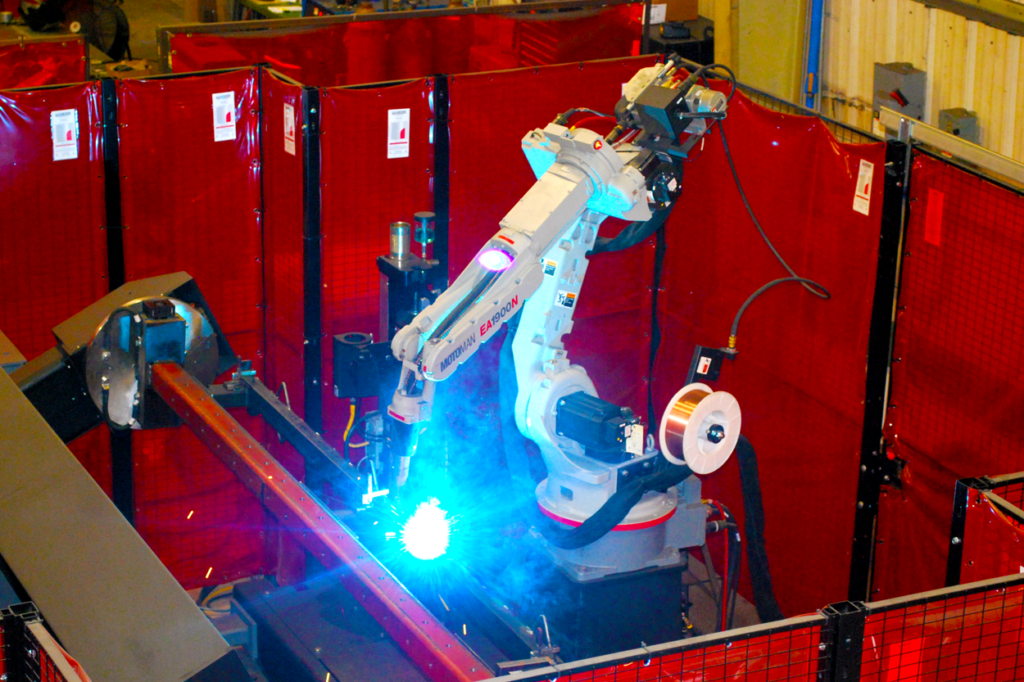

MOTOMAN ROBOTIC WELDER

The Motoman Robotic Welder is an advanced automation solution tailored for precise & efficient welding in manufacturing. Equipped with a sophisticated robotic arm and precision control system, it ensures high-quality, consistent welds. Its versatility allows it to handle a wide range of tasks, from intricate small components to large assemblies, making it a valuable asset for optimizing productivity and maintaining superior weld quality in various industries.